Engines

<< HOMETypes of engines:-

4. Generator Engine

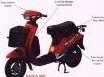

5. Moped Engines

6. Generator and Water Pump Engines

7. Reclaimed Go-Kart Engines

8. Car Engines

9. Tractor Lawnmower Engines

10. Rotavator Engines

There are a few more but the list above should cover nearly all the engines one can adopt to drive a Kart.

How to rate your Engine,

Horsepower

This is the exact power that your engine can produce. That is the crankshaft that comes out of the crankcase. It is the amount of energy required to lift 550 pounds, one foot, in one second. Therefore we can see that the greater the horsepower the more powerful the engine and the faster we can gear the Kart to go. Horsepower can be calculated if you know the kW of your engine. Eg. if an engine has a 14kW rating. You multiply that figure by .746 to get the horsepower, which in this case turns out to be 10.5 hp aprox. 1 hp = .746kW

Brake-Horsepower

This is the power that the combined engine, clutch and gearbox can produce. This reading is taken off the driven wheel. This is a much better and more accurate measure of the power of a vehicle. However if the chain is too tight then you reduce the bhp. Therefore if the drive is shabbily done then you are wasting power/bhp.

Kilo-watt Rating [kW]

This is another rating for the power of the engine by itself, ie. measured from the crankshaft of the engine. As mentioned earlier it can be calculated if you know the horsepower. In my opinion this is the truest reading of the power of an engine, as it takes into account the speed and power of the engine. You might have an engine with a cc of 160cc but a kilowatt rating of 5kw. Now if you have an engine of 100cc but a kilo-watt rating of 14kW, you can say that this engine is the better.

That is in my opinion the problem, because when people compare engines they only seem to compare them on the basis of their CC. But this is not a true indication. In the above example the reason the 100cc engine is nearly twice as strong is because is runs at revs twice as fast as those of the engine of 160cc.

Two-Stroke

Two stroke engines are much more power efficient than four stroke. The only problem is that they use more petrol and have bad exhaust emissions, because they burn oil as well as petrol. However if you have a two-stroke engine then you are in luck. These engines are robust, having no valves they can run much faster and have more acceleration. Another problem with these engines is the problem of burning oil to lubricate the piston and crankcase, making these engines prone to seizures. However as long as you have plenty of blue smoke coming from your engine then you are fine. With these engines expect more acceleration and more power coming out of corners.

Four-Stroke

Not all things are bad if you have these engines. They give good gas mileage ( if that is really important for off-road karting). If you happen to have over head valves then your engine can run pretty fast, but not nearly as fast as two-strokes. However with the correct gearing there is no reason for lacking speed. For every 2 turns of the crankshaft, 1 of them is power. (Note: there are two-strokes per revolution. Thanks to: Daniel DeLury)

Cubic Capacity [CC]

As I said earlier in the kilo-watt section cc is not a great basis for comparison of engines. It is only a rough guide. The bigger the figure the more petrol you will be burning every time the spark plug fires. 1litre = 1000cc

Revolutions per Minute [RPM]

This is another important factor in Karting. The greater the revs the more acceleration. However if it is a weak engine with loads of revs then the gearing will have to be set low. If your engine has a tachometer, this will tell you the rev's your engine is producing. However you shouldn't run the engine at maximum revs for more than 20-30 seconds. Anymore and you won't have much of an engine left. We will be using the rev's of an engine when calculating the correct gearing needed for a kart.

Air-Cooled

Nearly all small engines are air cooled. That is why it is bad for these engines to be run for long periods at a stand still. Cooling is provided by the wind which cools the cooling fins around the engine when the vehicle is moving at a fast pace. These engines can be clearly recognized with their large cooling fins. They are the best ones to have as you don't have to go messing around with radiators.

Water-Cooled

This system of using fluid which runs through the engine as shown in the picture. This liquid runs in turn to a cooling radiator. A fan may also be incorporated to cool this radiator if the vehicle is stationary. With water cooled engines, revs can be kept high without the risk of overheating. That's basically the only advantage.

Pushrod Operated Valves

This is where a short timing chain turns a camshaft mounted at the base of the cylinders, elliptical (oval or pear shaped) lobes on the cam push a rod up alongside the cylinder where it causes a rocker to swivel and push down on the valve, opening it to allow air/fuel mix into or exhaust gasses out of the cylinder. These limit the revolutions the engines are cabable of due to the rods having a regrettable tendacy to bend when the revs rise and the inertia of the rocers and valves becomes to great for the pushrods to move in sufficient time to match the rotation of the camshaft lobes.

Over-head Valves [OHV]

This is where there are valves operated via a timing chain turning a camshaft and rockers all mounted above the piston. This method has 2 versions, Rocker activated, there the camshaft lobes push directly on the rockers dicarding the pushrods used in the previous method discussed, or Bucket valves, where the camshaft is directly above the valve stems and pushes straight down on the valve to open them. Rocker activated OHV engines can reach higher RPM than Pushrod engines, but the rocker inertia is still present and excessive RPMs can cause a rocker to break. Bucket style valves have technical challenges to do with a rotating cam placing sideways stresses on the valve stems which renders them more expensive and more challenging to engineer and as such are mostly found on high performance racing and sports car motors, but allow engines higher revolutions than rocker systems.

Left -

OHV

Right - Conventional Valves

Left -

OHV

Right - Conventional Valves

Double Over-head Valves [DOHV]

This is a system the same as above only instead of 1 camshaft with different lobes on the same shaft operating the intake and outlet vbalves, there are 2 camshafts 1 for the intake and 1 for the outlet. Pushrod and OHV engines are typically 2-valve-per-cylinder engines, some rare OHV engines are 3-valves-per-cylinder engines, this is to do with the need to fit both intake and outlet lobes on the same camshaft. DOHV systems allow more valves to be fitted into the system by doubling the number of shafts. The increased number of valves means more area is provided when the valves are opened for the fuel/air mixture to enter through and the exhaust gasses to exit through, increasing the efficiency of the engine and the amount of power (Hp or KW) to be created from a given CC size engine. However, this is not always so, there are a number of 2-valve-per-cylinder Rocker based DOHV engines, where the single intake and exhaust valves for each cylinder are run off different camshafts, this is so each camshaft is running against inertia values which are lowered by having to run only half the number of rockers, this allows slightly higher RPMs than 2-valves-per-cylinder OHV engines.

Edits thanks to Rhys

Variable Valve Timing

This is where the timing of the opening and closing of the valves can be altered. Again the theory is that as high speeds are encountered in the ranges of 8000 + revs, conventional timing of the valves are less efficient. As the rev's go up then the valves are able to adjust so that the maximum efficiency of the engine is achieved. As the speed goes back down then the valve setting go back to normal.

Points Ignition

This is where the spark that ignites the fuel is produced via a set of breakers, which are mechanically operated via the crankshaft. The initial spark is provided via an alternator or magneto. This spark is then controlled and delivered at the correct time by the breakers. Most all small and old engines still have this principal. The breakers require maintenance now and again to make sure the gap is set correct.

Electronic Ignition

This is a more modern approach. A spark is initially produced as normal via a magneto/ alternator, but this spark is controlled and delivered via a "black box". This is called CDI. It stands for capacitor discharge ignition. There is no maintenance needed on this setup. However the downside is that if you don't know what you are doing and you happen to blow this CDI unit then be prepared to shell out a nice bit of money. Overall good to have.

Kick Start

This is where the engine is turned over initially via a kick start pedal to get the engine to fire. Most small motorbike engines use this setup. It is very useful on a kart engine as it is fairly robust.

Electrical Start

This is where the engine is turned over via a motor electrically operated by a switch. This is very useful if you stall the Kart. However this requires a fairly good battery to operate and all electrics are needed. And as usual if anything goes wrong with it, you will need patience.

Pull Start

This is the system used on all lawnmower engines. It is simple and easy. All it is, is a pull cord that turns the engine over to get it going. However be prepared for a sore arm if the engine is sick.

Torque

Measured in Nm ( Newton meters). This is the amount of turning force an engine has. And of course the higher the rev's the greater the torque. The torque will always be given with a corresponding rev's. E.g 1200Nm @ 4000rpm. This is saying that at 4000 rev's per minute the engine will produce 1200 Newton's per meter. On a Diesel engine the rev's will be lower. Again the more the torque the better, but be careful of comparing to make sure the rev's at which the torque is measured is the same.

Weight

Of course common sense will tell you that if the engine weighs a ton but is only 125cc and only does 4000rpm max, you are at a disadvantage. The lighter the engine the better. As engines get bigger and heavier you reach a point where the power and speed the engine puts out is not enough to cover the additional weight. It is called the Power to Weight Ratio. You are ideally looking for a highest possible ratio.

Compression

This can easily be checked by turning the engine over manually ( with HT lead removed). You should reach a point where it gets difficult to turn. This is the compression. The harder it is to turn the engine over at that spot only the better the compression. The greater the compression the more power that will be obtained as the fuel rich air is compressed greater the more violent the explosion will be giving more power.

Petrol

This covers most engines where the engines takes Leaded or Unleaded petrol in the tank. You can however if you want to mix some leaded and unleaded petrol to give a high octane fuel getting more power from the engine at a loss of engine wear.

Diesel

On Diesel engines there are no spark plugs. The way the explosion happens that drives the piston downward is the fact that as the Diesel fuel is compressed Very Highly, there reaches a point where the diesel will automatically combust. This does away with the need for points and spark plugs. The only disadvantage is that as compressive forces are higher the harder it is to turn the engine over, requiring bigger starter motors and more powerful batteries with a higher ampage.

All of the List above cover to the best of my knowledge the facts needed in rating an Engine. Some are far too advanced for normal Karting. But some are of real importance, eg. revs, 2/4 stroke, cc. etc.

The list above however only rates the engine, not the drive which may be included in some engines eg. motorcycle engines. If you are fortunate enough to have some sort of a gearing system built into to you engine, then we must see if it will be enough to drive the kart without needing any major work.

Gearbox-

This is a fairly important piece of kit, especially if you are building an off-road Kart. A gearbox gets the most out of the engine you are using. Without a gearbox you have a restricted speed range. 0-30mph. Whereas with a gearbox 1st gear could be 0-25mph and 2nd could be 25-50mph.

Different gears can be selected via a selector arm coming out of the gearbox at some point. On a motorcycle however, to get from 4th to 1st you have to go down through all the gears, unlike with cars, where 1st or any gear can be selected from neutral. The same with rotavator engines ( the self driven ones). On a tractor-lawnmower engines there usually is only 2-3 gears, not making much difference.

It doesn't really matter how many gears there are. It matters more about the gear ratio between the gears. The bigger the ratio the bigger the speed difference, however the stronger the engine you will need to facilitate this big jump in speed. The closer the gears are spaced together the smoother the transition between the gears and the less the demand required from the engine. Usually 3 to 4 gears are all you'd need for any kart. Any more and you will have a problem keeping the weight down.

The way racing Karts get around this problem is to have a very high gear ratio and to let the clutch slip like mad starting off and then grip fully until an acceptable speed is reached. Of course you would burn out a Lot of clutch pads. However for some engines this is the only way. As you will see with the lawnmower engines section.

Clutches

After the engine this is the next most important section of the drive of a Kart. Unless you have an extra set of hands every where you are with the kart you will need a clutch, whether be it a simple fan belt tensioning system or a friction clutch in a bath of oil. In my opinion a clutch IS a MUST, there is no way around it. I got very quickly fed up with having someone to push start the kart with me in it. I even tried running the wheels on blocks and then trying to rock the kart and take off when the kart hit the tarmac. With all of the engines I listed above I have suggested the best clutch to use in my opinion anyways.

Types of Clutches:-

Dry Clutches,

This covers most of the clutches including racing and belt clutches. Basically all it means is that the clutch is not immersed in any cooling liquid. It is air cooled and gives more bite when engaged making it apt for racing bikes. Most clutches in car's have dry clutches

Wet Clutches

This is where the clutch is immersed in a bath of oil or some other fluid. This has the advantage of keeping the clutch pads/friction plates cool, as well as reducing the amount of ware. This type of clutch takes a lot more punishment, as long as one keeps the oil up to the correct level. If it were to run dry then it would not last long.

Racing Clutches

Nearly all of these clutches are of the Dry Type, mainly because there is more friction. However these run hot and they would only last a couple of races then needing to be renewed.

Manual Clutches

This covers any clutch which has to be engaged manually regardless of engine speed. It is either operated by a pedal or by a lever running via a cable from the clutch housing. In my opinion these are the best type as they give the smoothest gear change. However the disadvantage is that it takes a bit of getting used to, a bit like on a manual car. Also you can have much more fun with burn-off's etc.

Automatic Clutches

These clutches are usually operated by engine speed. As the accelerator is depressed the vehicle moves. You will find these clutches on chainsaws, mopeds and automatic cars, buses etc. The main advantage is that only one pedal is required to move the kart. However these clutches suffer from slipping especially if the gearing is set up wrong ( too high ). These clutches can either be wet as on mopeds or dry as on chainsaws.

Centrifical Clutches

This type of clutch is the one which covers nearly all of the Automatic Clutches. It uses centrifical forces. I.E. as the speed/ rev's increase the more the forces are experienced. This is the type of clutch used on chainsaws and petrol hedge trimmers, and it is usually "dry". This type of clutch is also used on mopeds and are of the "wet" type. More about these are in the Moped section in the beginning of this page.

Belt and Tension Clutches

This is a fairly crude setup, however as long as the gearing isn't too high less slippage is encountered. If slippage occurs then the belt will heat up and wear very quickly. On very early motorcycles this was the sort of clutches used. I will be referring to this in the Lawnmower Engine section in the beginning of this page.

You can see in the above picture that the pulley circled in yellow is brought in to tension/tighten the belt so that it will now grip on the pulleys and provide a drive.