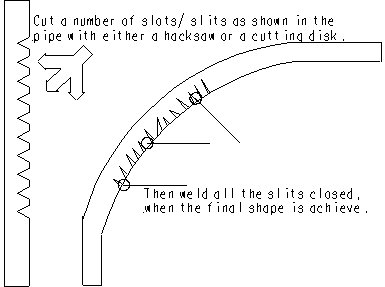

Last resort in pipebending.

This method on the left is on of the ways you can use to bend a section of 25mm pipe. However it is a very rough procedure and requiring tidy welding of all the slits when the desired curve is achieved. Also a smooth curve will be very difficult to achieve. But with a bit of patience and perseverance you will achieve the desired shape.

Another method of producing a curve in a pipe is to, Firstly : Blind off the end of a small section of pipe only the length of the curve, by welding a cap over the hole. Secondly : Put a small amount of sand into the pipe. Thirdly : get a steel bar and tap the sand in the pipe compressing it. Put some more sand into the pipe and compress it. Do this untill the pipe is full of compressed sand, then weld on another cap on the open end.. Fourthly either bend the pipe using either the cold or hot method. I'd say that just putting the pipe in a vice and using brute force you will be able to produce a smooth curve although not accurate. Finally cut off the caps on both ends, rake out the sand, and weld this small section into the chassis.

Which ever method you choose to use it will still be a crude curve. GOOD LUCK. !!